Purchase / Scheduling Agreement

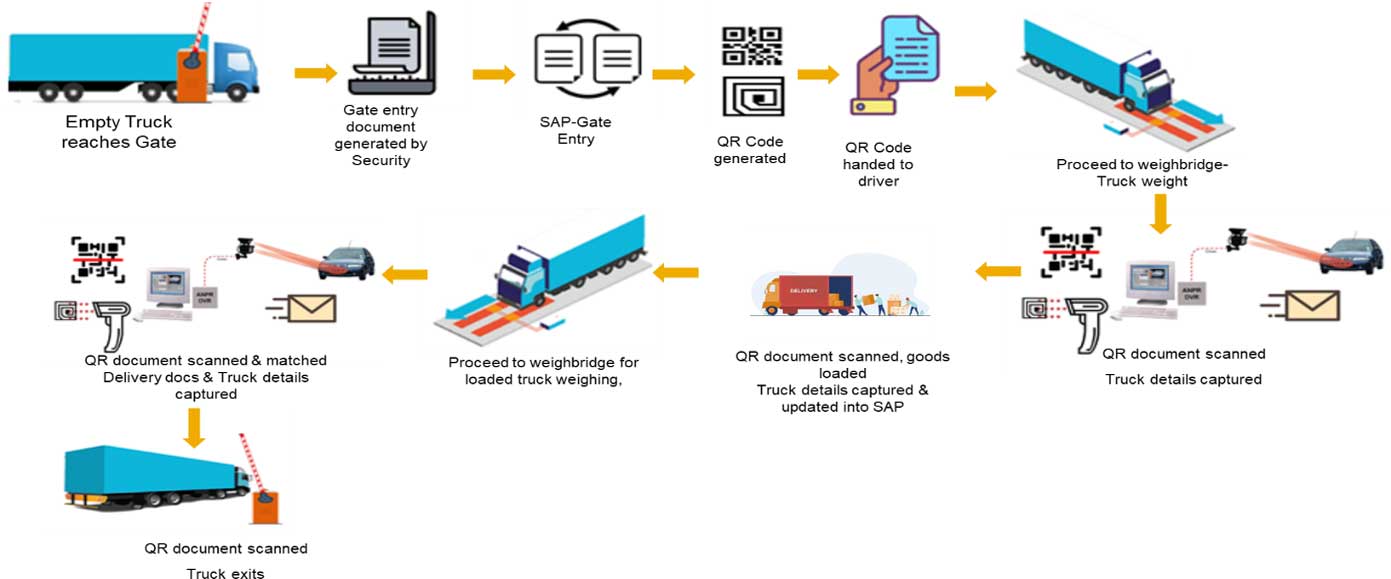

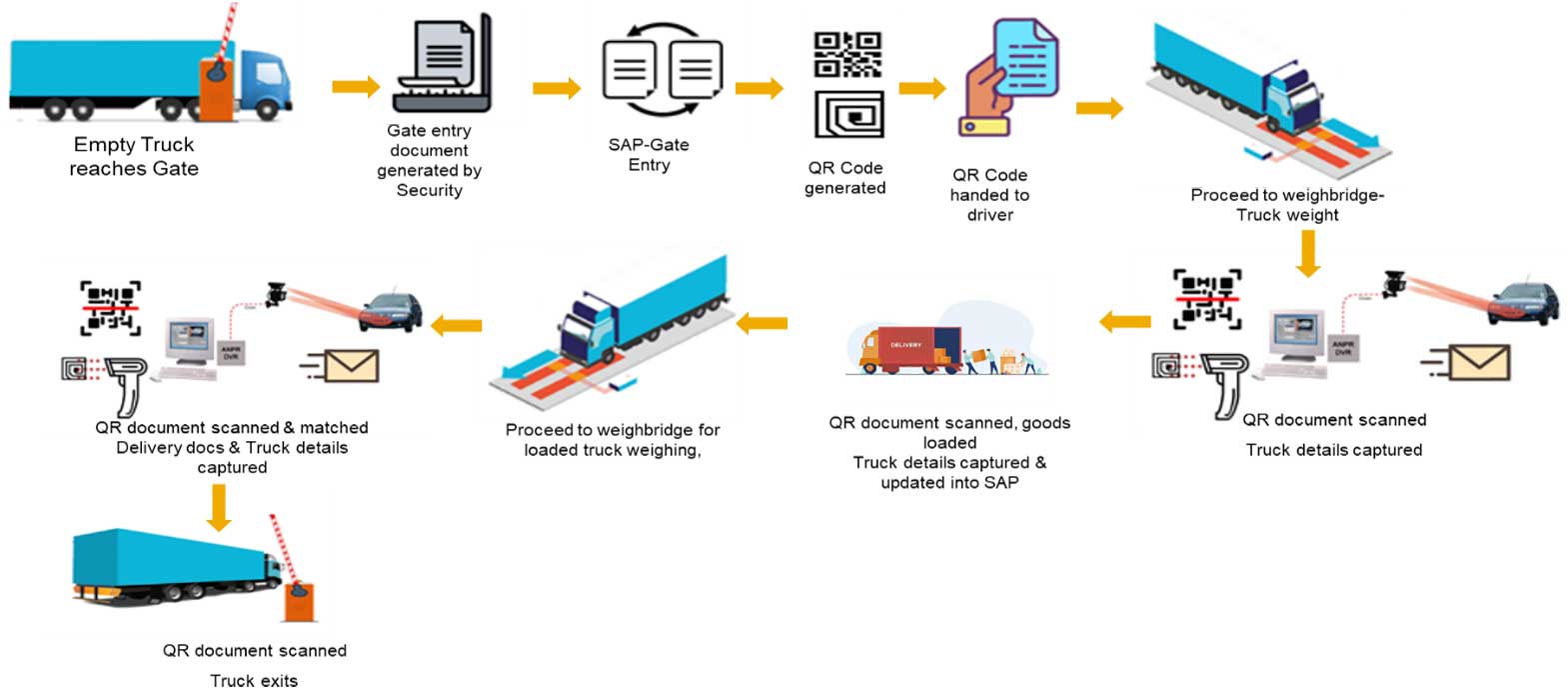

Gate entry is done for the material received at the warehouse from the vendor related to the purchase order or scheduling agreement issued to the vendor.

The process of movement of materials to and from the premises in any organization, and to keep track of all inward and outward movement of materials or other locations, is termed as Gate Entry.

“Gate Entry” is a proprietary SAP Enhancement Product; it is an advanced version of LECI functionality of SAP Logistics. The Solution has been designed to streamline the Inbound receiving process and outbound delivery process. Gate Entry integrates the usual purchase order process with a tool that will allow you to record both inbound and outbound weights of the truck load, and has significantly more integration functionality with the MIGO transaction. The solution can track incoming/outgoing materials; stop gate entry; prevents the theft or unauthorized carry. The solution improves the accuracy of the purchase orders by automatically compensating for differentials between what was ordered and what was actually delivered.

Gate entry is done for the material received at the warehouse from the vendor related to the purchase order or scheduling agreement issued to the vendor.

Gate entry is done for the original material received from the customer to do work on that material.

In this process, a gate out entry will be done for the material returned to the vendor due to any quality issues or other reasons with respect to the material.

Gate entry done for the material transferred from one plant to another plant.

Gate entry done inward for any returnable or non-returnable material.

Gate Out for any returnable /non-returnable material.

Gate entry done for any defected material returned by the customer after sales.

Gate Out for the material that goes to the vendor for work.

Weighing (Automated / Manual) for Acceptance / Rejection

Storage Verification

Goods Receiving Confirmation

Goods Return Management